June 12th, 2020

Week 13

Attended the SU2 Conference Day 3 - Livestream to hear Jayant Mukhopadhaya's closing presentation on how the SU2 Foundation has been supporting the Worldwide Ventilator project. Well done Jayant! Big shout out and thank you to all the volunteers that have helped along the way and to all those that are still contributing to this great effort. 👏

June 2nd - 8th, 2020

Week 12

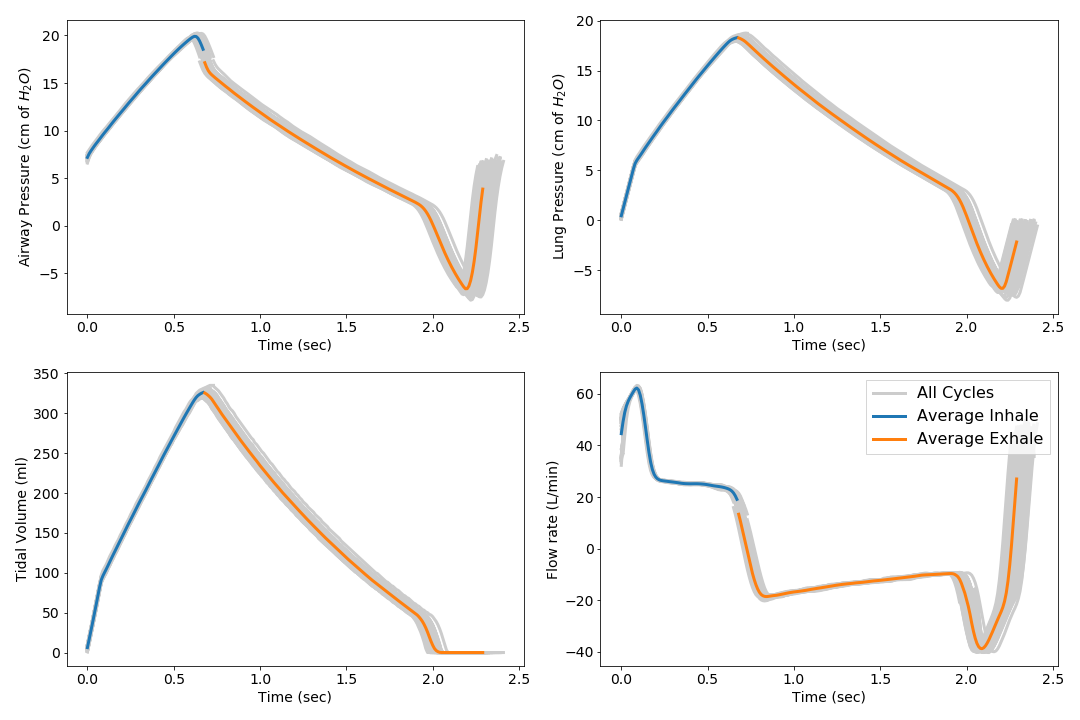

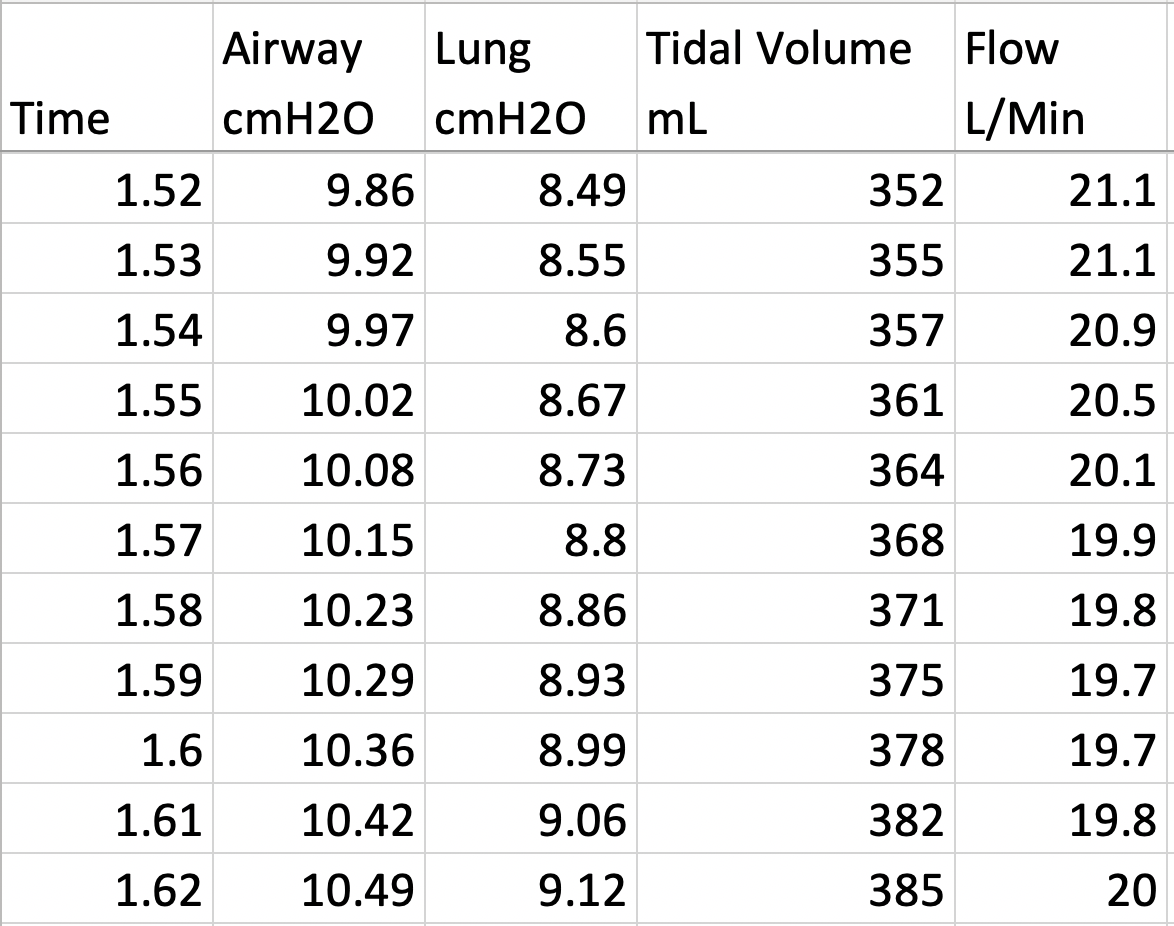

We are pleased to share that with our Rev15C1 prototype we were able to hit a safe range of operation for respiratory rate, tidal volume, I/E ratio, inspiratory pressure, and PEEP. 🎉 Click here for full test report. See our April 28th - 29th, 2020 update below for more context into why we have so many set screws.

- Input Pressure: 2.2psi

- Lung Compliance: .02 L

- Respiratory Rate: 23bpm

- Tidal Volume: 450 mL

- I/E Ratio: 1:1 - 1:2

- Inspiratory Pressure Limit:

- Peep: 5-6 cm H20

May 26th - June 1st, 2020

Week 11

The Rev15C prototype is much easier to work with, way more control than previous models. Excited to get the PEEP out of the negative but still not in an ideal range. Below are some high-level data points on how it performed. Click here for full test report . Bonus points if you know the song playing in our video.

- Input Pressure: 2.2psi

- Lung Compliance: .02 L

- Respiratory Rate: 15bpm

- Tidal Volume: 400-450 mL

- I/E Ratio: 1:2 - 1:3

- Inspiratory Pressure Limit:

- Peep: 2 cm H20

May 19th - 25th, 2020

Week 10

- We are finding that we need to run our Rev15B prototype at 2 psi instead of 5 psi to allow for optimal performance.

- Once we dropped to 2psi the Rev15B prototype behaves a lot better than the Rev15 model did. We are happy to see a lot less variance in the flow rate. The inhale:exhale ratio, tidal volume, breath rate, and pressures are hitting reasonable target ranges. We were not able to maintain a positive pressure PEEP.

- Next we are planning on testing our Rev15C, and Rev15D.

- Attended Vent-CON 2020 that was hosted by Public Invention, Helpful Engineering, and Make Magazine.

May 12th - 18th, 2020

Week 9

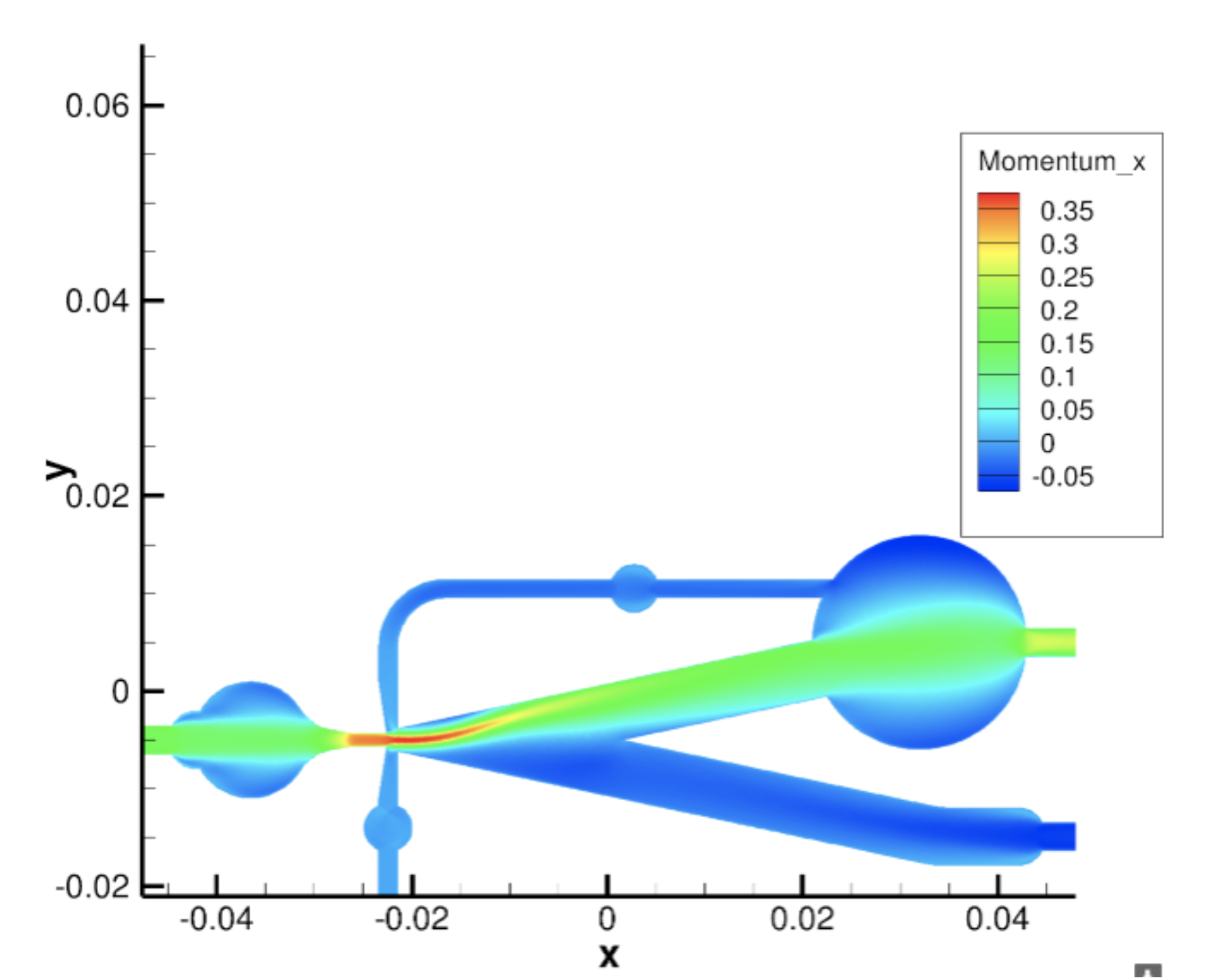

- Collaboration with our CFD team is picking up!

- We have introduced a new testing structure that puts our raw data in context of the ideal ventilator ranges.

- Working on replicating the same settings in our CFD simulations to validate our virtual models are functioning the same way as our physical devices.

- We are struggling to get our Rev16 prototypes to oscillate. Will be focusing on our Rev15A, Rev15B and Rev15C iterations for now.

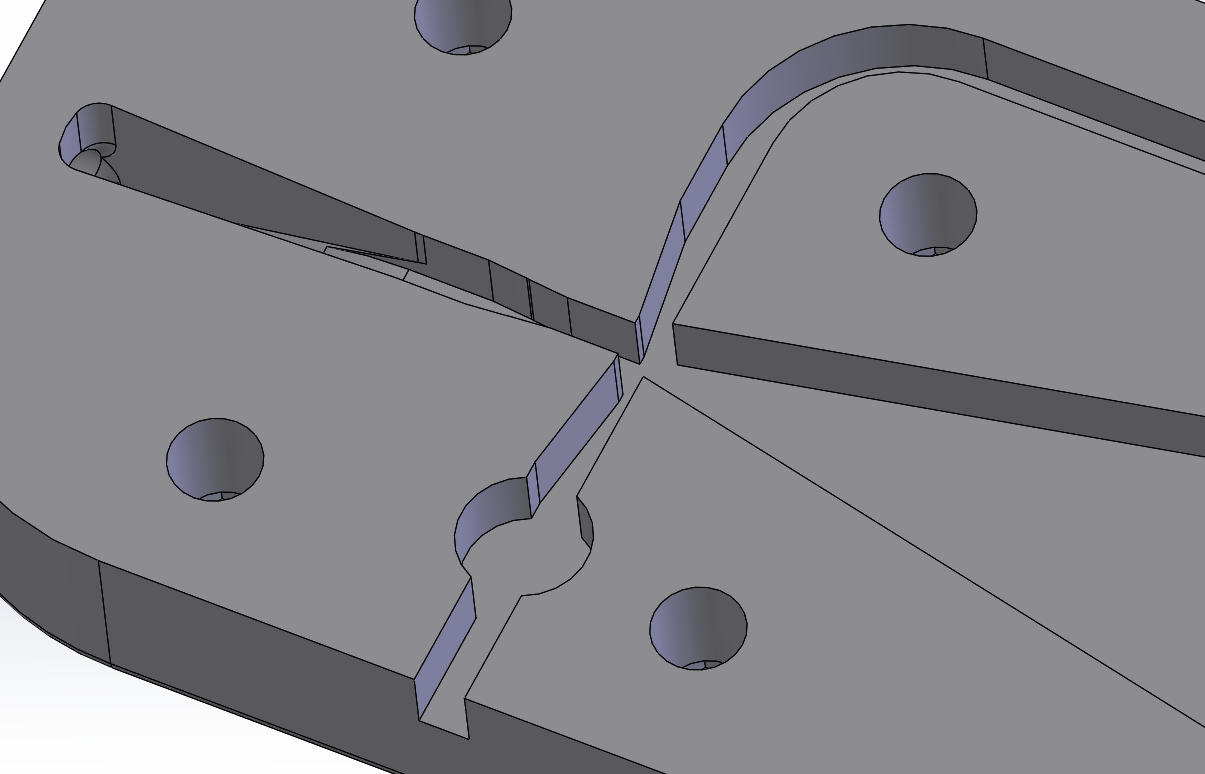

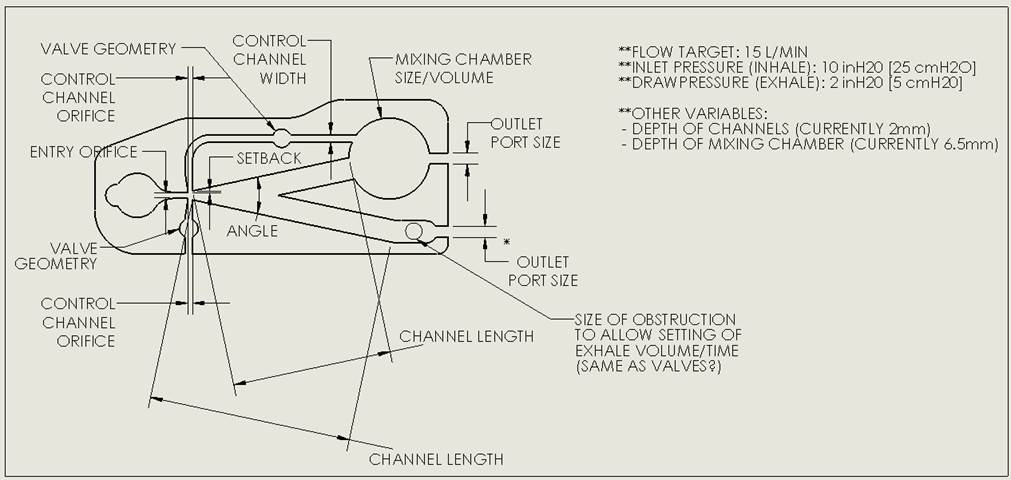

- Also looking into designing a Rev15D iteration with with a 2.8mm DP channel. Looking deeper into the ratio of the nozzle height/width. (See Featured image)

May 9th - 11th, 2020

Week 8

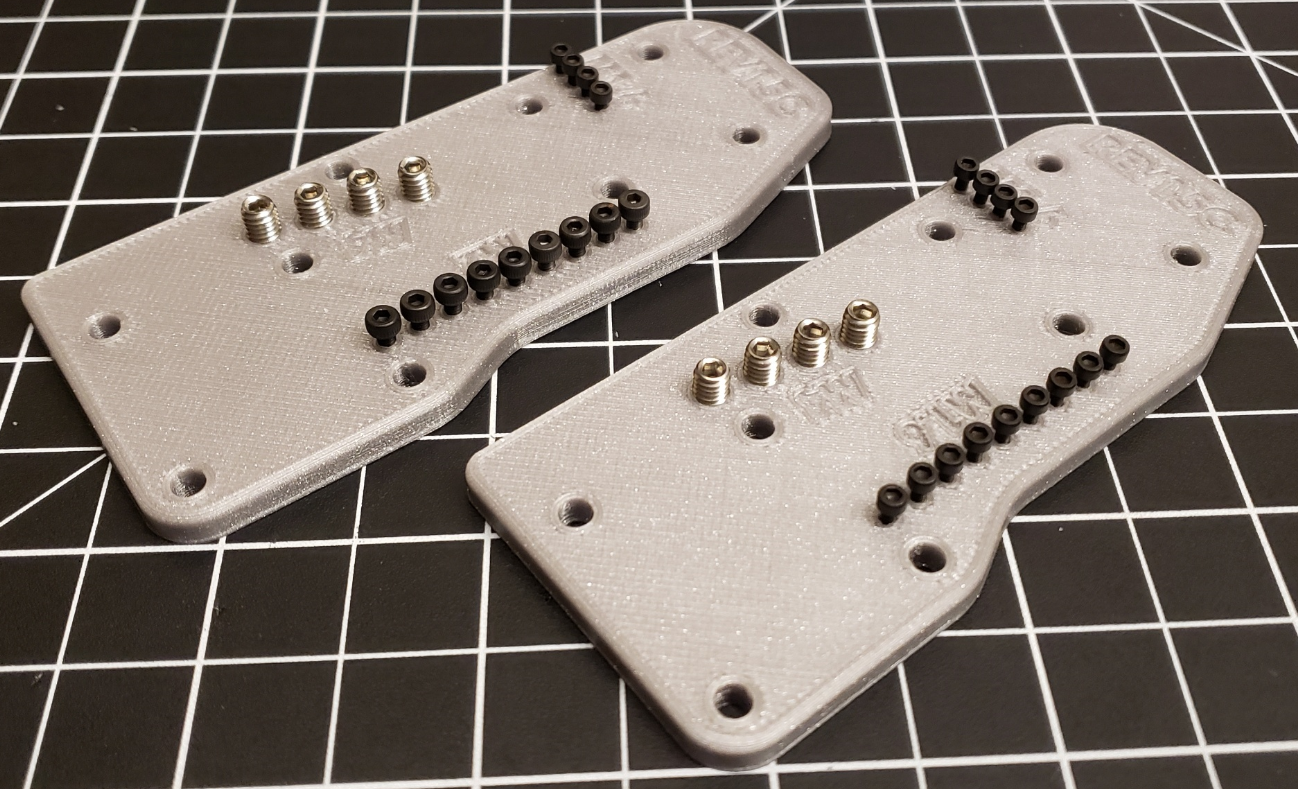

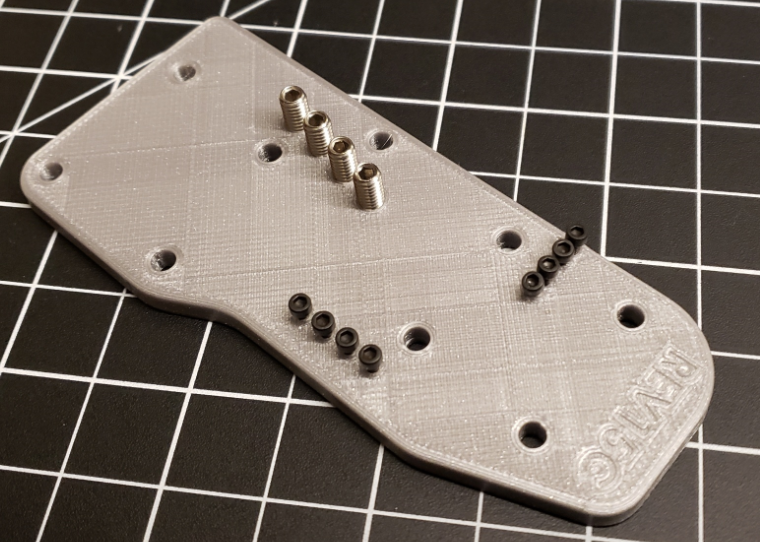

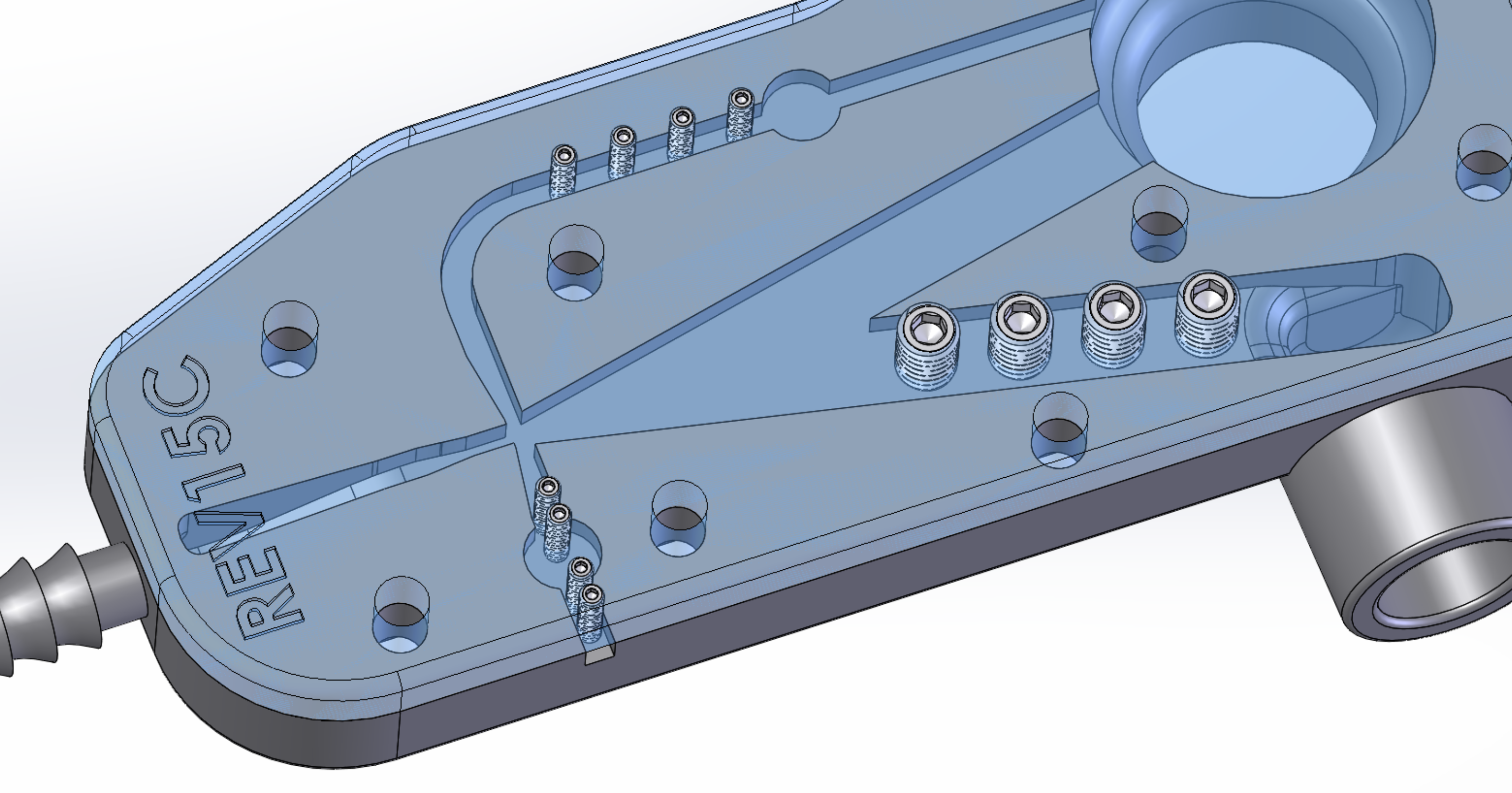

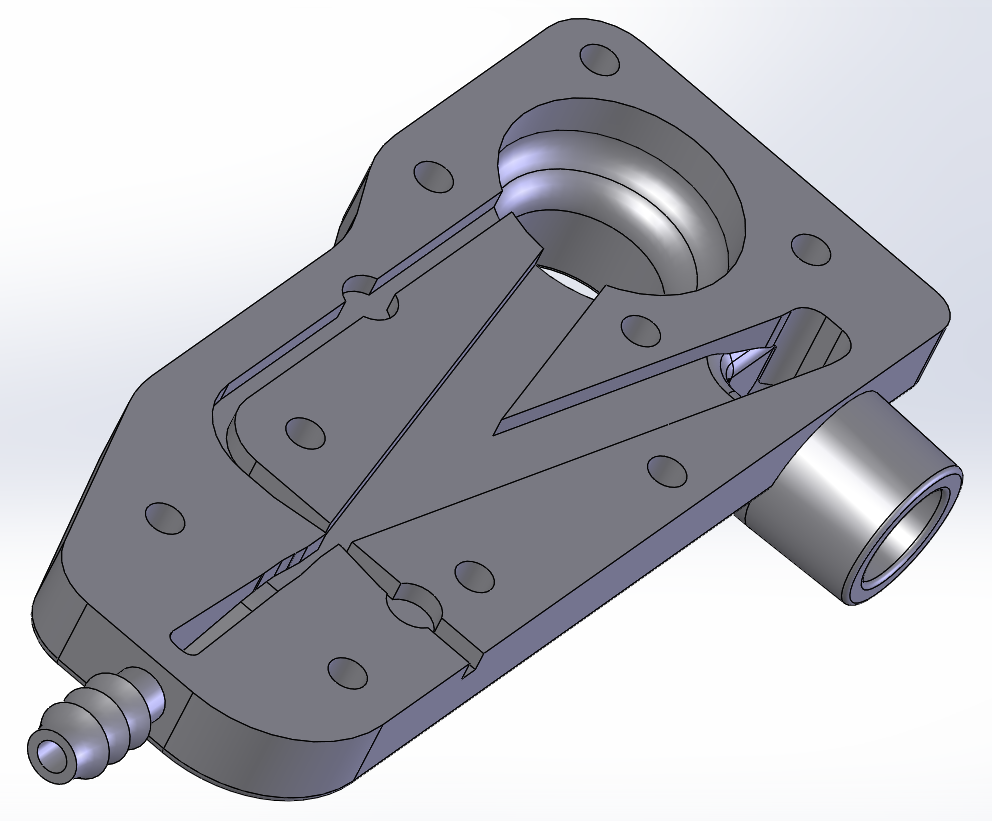

- New Rev15A, Rev15B and Rev15C assemblies printed and ready for testing. Here is a description of these revisions:

- Rev15A: updated exhaust channel with fillets on exit port to smooth the transition. Internal geometry is the same as previously sent to CFD team except for this feature.

- Rev15B: Rev15A but removed entry mixing chamber -- now a straight line in.

- Rev15C: Rev15B but with multiple M1.6 and M4 set screws within the channels for valves, for testing if it gives better control of set points.

May 7th - 8th, 2020

Week 8

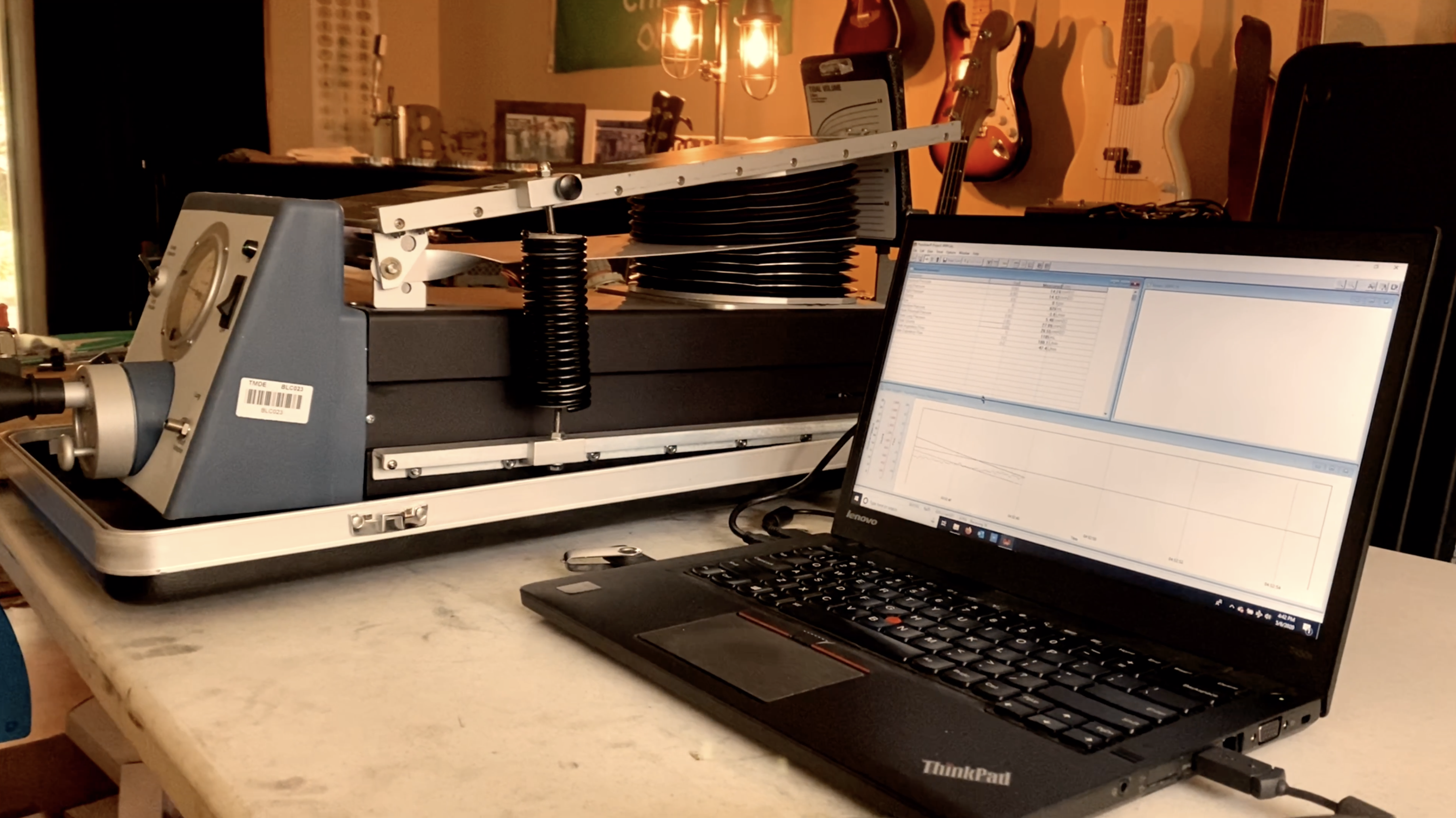

- Gathered data from the Michigan PneuView 3600i test lung and have sent it to the CFD team for analysis.

- Advice from medical professionals continue to come in. Thank you!

May 5th - 6th, 2020

Week 8

- Received software for the Michigan PneuView 3600i test lung and got it setup and ready for testing.

- Working on 3D printable set screws that would allow for a better user experience and onboarding.

- Held a phone call with the CFD team to refine the data needed for validating the simulations they are running on the latest prototypes.

- Documentation and research continues.

May 4th, 2020

Week 7

- Rev15C prototype is printed and ready for testing. It has M1.6mm screws in the 2mm control channels, and M4 screws in the 6mm exhaust channel. We have also printed a couple of Rev16 assemblies for testing.

May 2nd - 3rd, 2020

Week 7

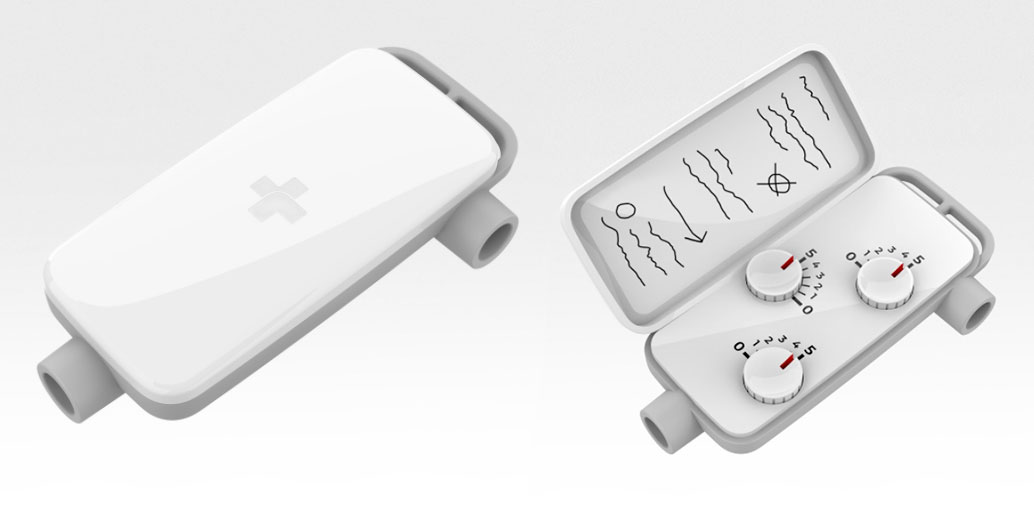

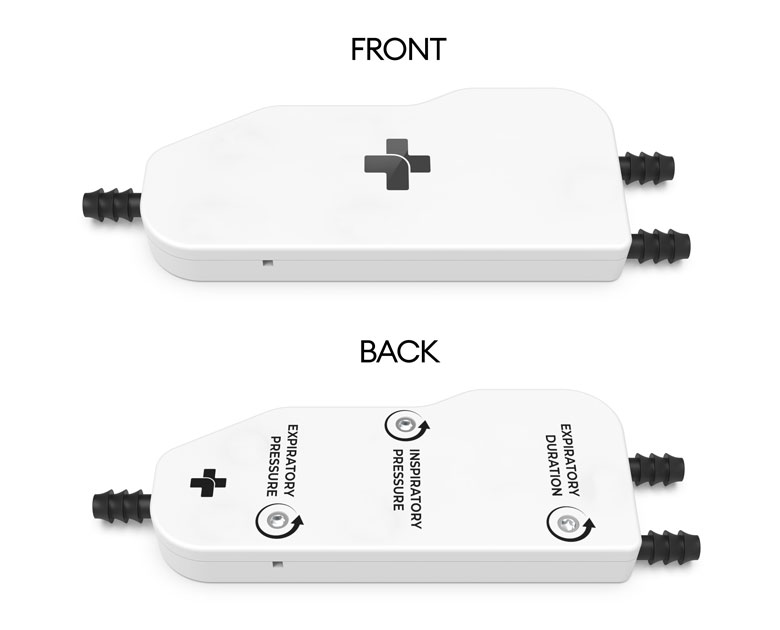

- Latest design concept of what the final product could look like. The front cover would prevent the more ergonomic knobs from inadvertently being changed and could also double as additional space for instructions on how to operate it.

April 30th - May 1st, 2020

Week 7

- Held an all hands meeting to discuss the outstanding risks to the project and gathered critical questions from the team that still need to be addressed.

- Testing and documentation on the device and how it works continues.

April 28th - 29th, 2020

Week 7

- Experimenting with adding a series of set screws that don't fill the full channel width instead of just one set screw as it is today. Due to the h^-2 law in resistance (h being the height of a channel), if you halve the width of a channel, you decrease the flow by 4x. However, if you were to place a screw in the middle of a channel that doesn't fully block the flow, you'd have less flow disruption from tightening that screw. But because that might not give you the dynamic range you want, you'd add extra pins in a row, so if 1 down isn't enough, 1 down and 1 partly down might be.

April 26th - 27th, 2020

Week 6

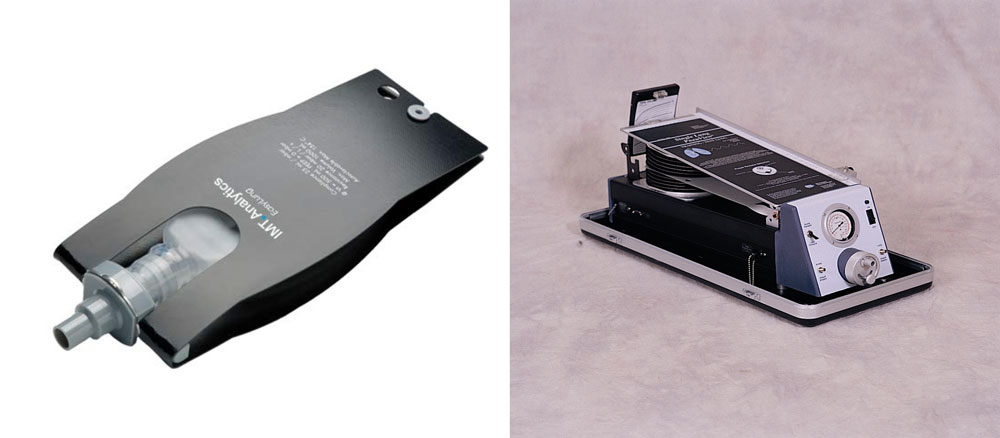

- Working on getting our IMT Analytics EasyLung 1 Liter and Michigan Instruments Single Lung PneuView Model 3600i Training Test Lung integrated into our test bed. This will allow us to accurately test our device against various ranges of lung compliance and oxygen intake.

- Testing is getting pretty heavy as we adjust set screw positions through all reasonable ranges/variations.

April 25th, 2020

Week 6

- Testing and iterating continue.

- As we come to a better understanding of the prototype's limits, we are considering the need to create different sized devices to address the needs of different patients with varying lung compliance.

April 24th, 2020

Week 6

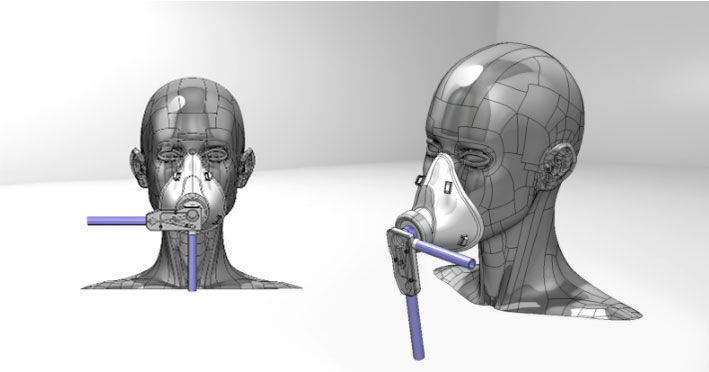

- With ventilated COVID-19 patients typically on their stomachs for about 16 hours a day, we have been thinking a lot about how we could make our device more comfortable as they move in a hospital bed.

April 23rd, 2020

Week 6

- Held a meeting with Juan Alonso with the SU2/Stanford CFD team. Working to provide validation data to ensure that the CFD simulations are in line with what we are seeing in our device testing.

- Met as a team to better align on how we can create more comprehensive data sets that can be organized and shared to help influence improvemnts in the design.

April 22nd, 2020

Week 6

- Usability research continues around more advanced dial/knob concepts. Here we explore the idea of locking in specific adjustments. Watch the video to see how we might do this.

- Had a very productive meeting with a professor in Pulmonology, Dr. Nicolls. One key takeaway from this discussion was the excessive amounts of fluids he is seeing in the lungs of COVID-19 patients and how this has to be addressed. We are working on ways to prevent such fluids getting into our device to prevent malfunction.

April 20th - 21st, 2020

Week 6

- Our Dial/knob concept #2 is set coplanar with the device and could be rotated with your finger. Watch the video.

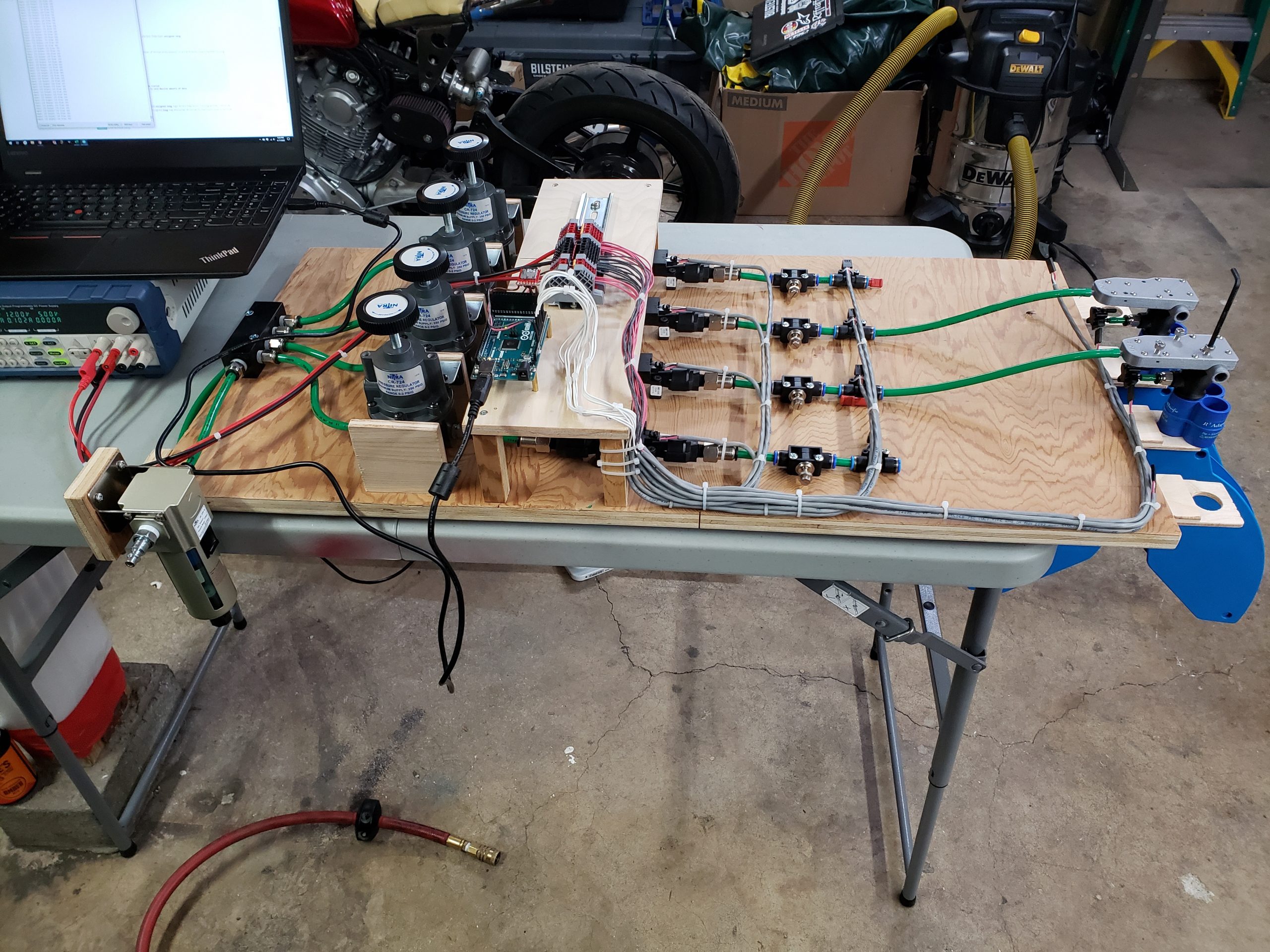

- We are finalizing the software (Arduino) for final implementation on the test bed but the wiring & pneumatics are complete and the sensors are operating correctly!

April 18th - 19th, 2020

Week 5

- As a result of our usability testing and research we are working other concepts for our dials/knobs. Watch the video to see how the design could be improved for those using it in the field.

- In order to reduce dead space we need to affix our device as close to the patience mouth as possible. We are considering adding D-ring type attachments to secure it in place since patients need to be turned intermittently for routine care and patients can thrash and move in their beds.

April 17th, 2020

Week 5

- Wiring completed and getting the sensors working on the test bed. Next we will need to write the software. Eager to get this operating for quicker experimental research and replicable testing.

- Testing and innovating continues.

April 15th - 16th, 2020

Week 5

- Excited about the progress of our test bed. Pneumatics are nearly complete. We plan to tackle wiring tomorrow.

- Continuing research on testing requirements for emergency ventilator.

- Realizing a need to differentiate between "Pressure applied to an inlet/outlet port" and "pressures inside the device". Looking into how this could affect the fluid calculations for pressure drop along the feedback channel.

April 14th, 2020

Week 5

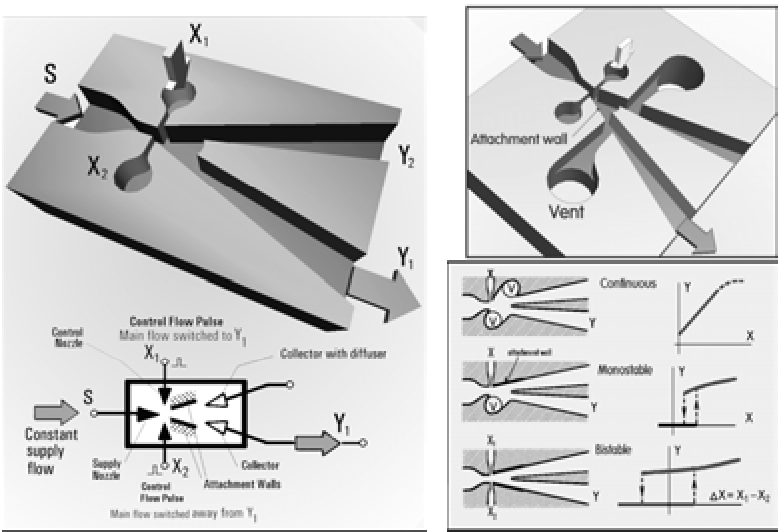

- We've seen from the literature search that many of the more stable "bistable switches" have vents to atmospheric pressure along the length of the output channels, increasing overall switching speed. Considering prototype variations with this variation.

- More testing and research continues.

April 13th, 2020

Week 5

- Started on some specific design revs for testing inflow channel geometry, and variations to narrow down on channel depth, setback and angles. Have parts on the printer tonight for testing inflow channel geometry.

- Collaborated with the open source team ARMEE Vent after discovering them last Friday. Discussed future paths together since our product concept and passion is similar. Sent a test lung to help them with testing.

April 10th - 12th, 2020

Week 4

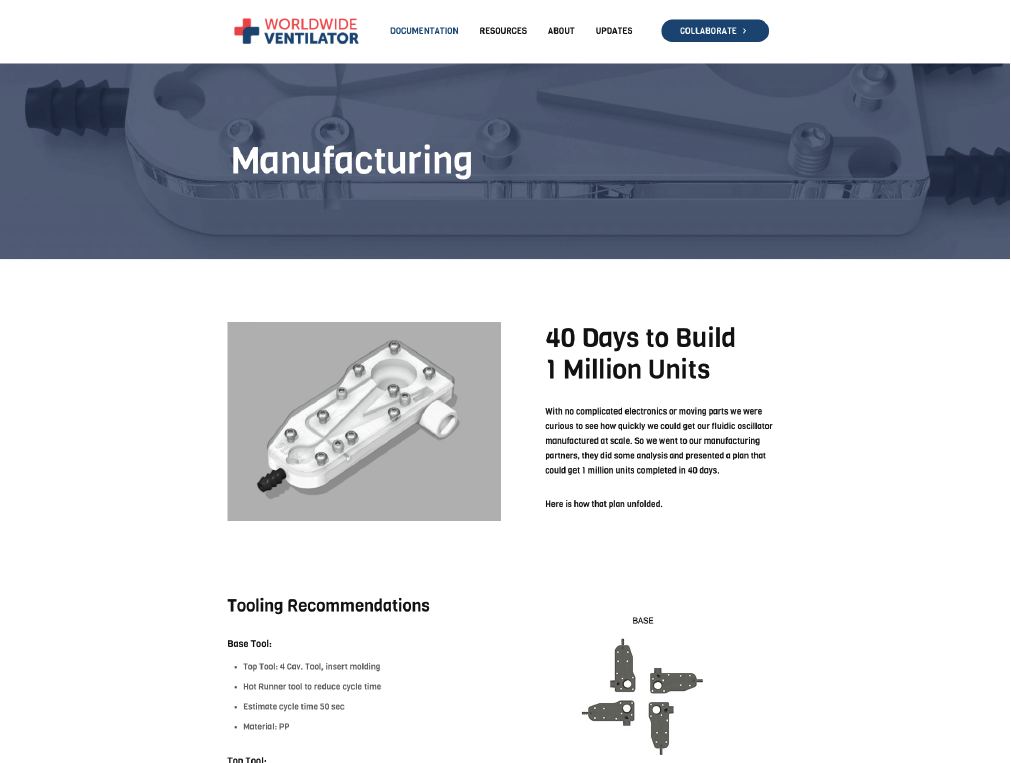

- Manufacturing partners estimate it could take as little as 40 days to produce 1 Million prototypes. Check out our Manufacturing page to learn more.

- Testing continues. Finding limits to how much we can push the designs. Coming to a better understanding of some of the prototype's limits.

April 9th, 2020

Week 4

- Video update of the our Rev15 prototype running at at Rp = 50cmH20.

- Switched our test lung orifice from an Rp of 5 cmH20 to 50cmH20, this required some tuning and our nylon material (black) didn't work. The PLA (Silver) material did work.

- Purchased a Michigan Instruments 3600i Test Lung. This should give us better low-compliance testing insights.

- Found the ARMEE Vent project on the Analysis of Open Source COVID-19 Pandemic Ventilator Projects

April 8th, 2020

Week 4

- We are setting up a test bed so we can test qty:4 prototypes at a time.

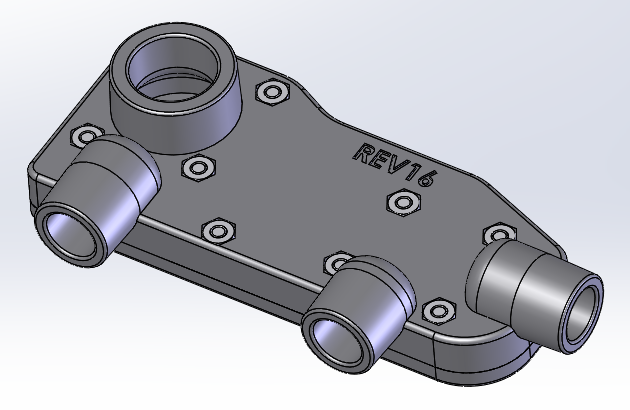

- The first Rev16 device will start printing on the Markforge tonight.

- Rev16 adds 15mm ports for ease of access to common hospital equipment and for putting a filter on the static control channel as needed.

April 7th, 2020

Week 4

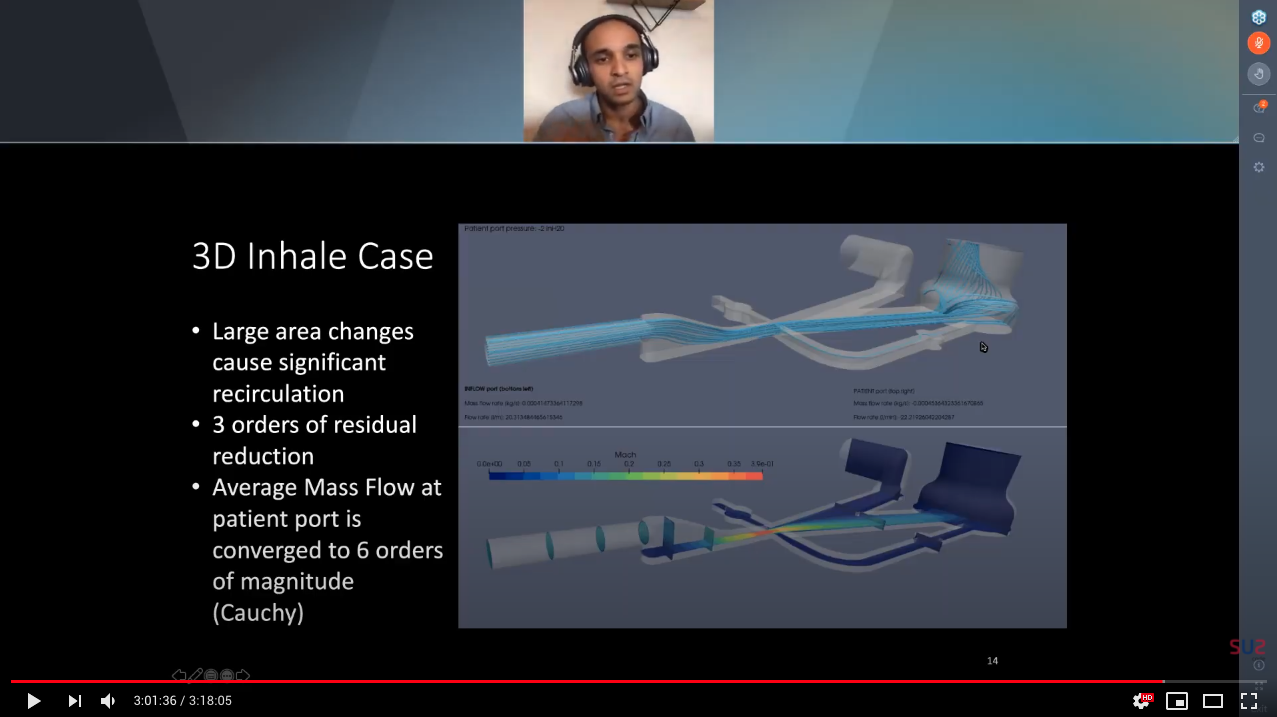

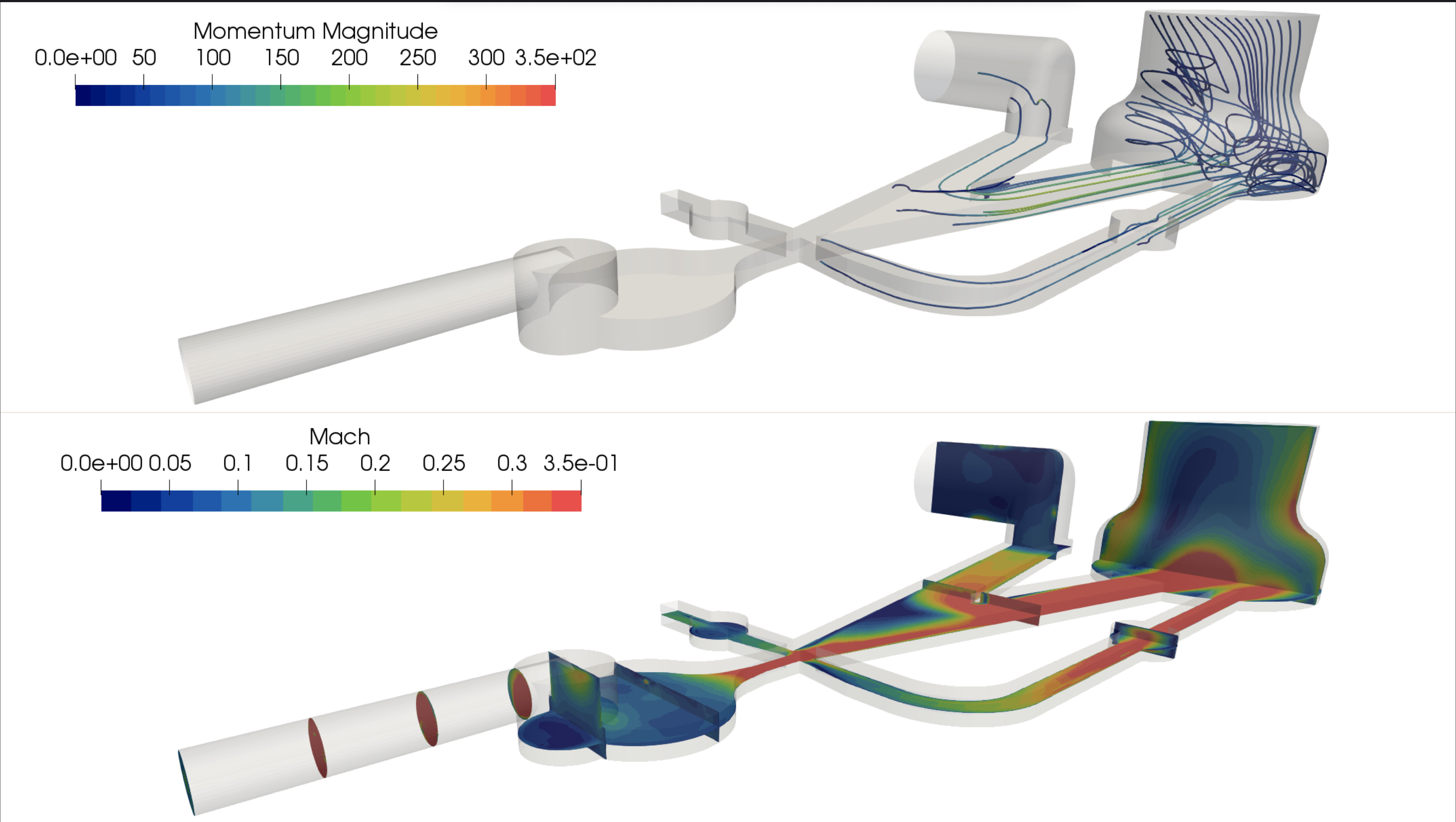

- SU2 Team's First 3D simulations ongoing….exhale state (still tweaking BCs) with latest geometry.

- Modified the exhaust geometry to make it simpler and improve the 3D meshing for analysis of the fluid channels.

- Made more clearance around the 22mm port for attaching tubes or devices.

- As of Rev14, we no longer need sealing gaskets any more and Rev15 is on the printer!.

April 6th, 2020

Week 4

- Super happy about our latest tests with Rev14. We are getting a 10inH20 high pressure switch-point and ~3inH20 low pressure switch-point. We are also able to adjust the rate via its exhaust set screw. [Watch Video]

- Sent a prototype to a health respiratory team for 3rd party analysis and feedback.

April 5th, 2020

Week 3

- Had an amazing meeting with the CFD team, made up of people from the US, Germany, Italy, Israel, England, Scotland, and Netherlands.

- Received early looks at our prototype getting setup for more advanced CFD analysis.

- Already printing Rev14 parts with the larger 22mm and 15mm ports. Will be assembling and testing tomorrow.

April 4th, 2020

Week 3

- Designing our 14th iterative ventilator with ports for standard hospital tubing.

- Long day in the lab testing while laser cutting clear top plates and gaskets.

April 3rd, 2020

Week 3

- On our 13th iterative prototype design and now testing on an artificial lung model.

- Held conference calls with ZIAN and MUSC for collaboration.

- Gaining a lot of attention and doing our best to scale with the influx of support we are receiving. Thank you all!

April 1st - 2nd, 2020

Week 3

- Kicked off the process of CFD (computational fluid dynamic) analysis for our ventilator. We are looking to find which variables have the greatest effect in the operation of the device.

- Thanks to the team of CFD volunteers through Stanford (SU2 code open source community) and other individuals from companies like Amazon etc.

March 31st - April 1st, 2020

Week 3

- Talked with a philanthropic organization to get feedback. Thank you!

- Exploring branded design concepts for the ventilator housing.

- Designing and printing new parts for testing channel height with internal control lines.

March 29th - 31st, 2020

Week 3

- Website created and pushed live (~72 hours) to seek out partners for medical testing and co-development.

- Testing channel angles as a variable; creating a new test prototype design with interchangeable inserts.

- Design is evolving every day, so we’re holding on posting files until we get a few parameters figured out.

March 23rd - 29th, 2020

Week 2

- Started investigating injection molding options for quickly manufacturing high quantities.

- Got a prototype to start oscillation by temporarily blocking ambient port.

- Tested height of channels as a variable; created new test prototype design with 1mm thick inserts to vary channel height.

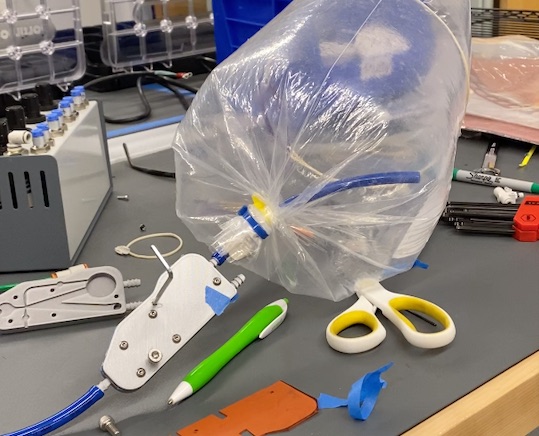

- Set up a demo with an inflatable bag for video to show progress.

March 17th - 22nd, 2020

Week 1

- Started brainstorming for alternate and simpler ventilator designs.

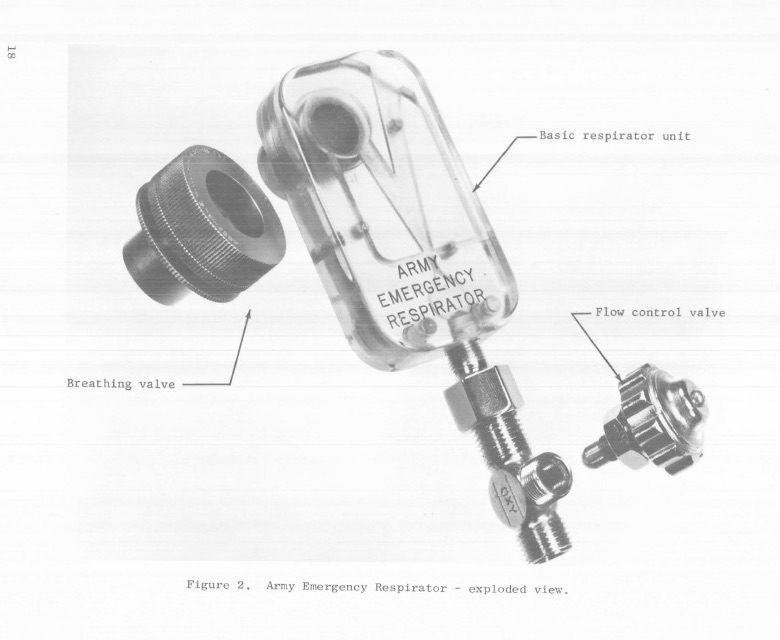

- Found the Army Emergency Respirator, developed in the 1960's.

- Started the mechanical design of a bistable amplifier / fluidic oscillator suitable for this application, based on the Army Emergency Respirator concept.

- 3D printed first prototype to test.